Behold the mighty, er, Giannini 650NP? Right then, fat little tires and fat little fenders all in the service of a rip-roaring air-cooled twin, 650 cc, about 40 horsepower, apparently driven by one M. Leonardelli to a number of European hillclimb wins in Group 2. KMP transkit for the Tamiya Fiat 500F. Loads of fun and a quick build for my second build of 2025.

24th-scale

A blog devoted to sharing my adventures building 1/24 (and 1/25) scale model cars, whether styrene or resin. Enjoy!

Monday, November 10, 2025

Monday, November 3, 2025

Porsche 917/30: Complete (first one for 2025!)

Yes, I have completed only one kit in 2025. Life got in the way.

Posed here with my selection of 908 and 917 kits. The first 908, on the far left, was really a 906 with the new 3 litre flat 8 engine, but the 908/03 shared a chassis with the 917.

The Can-Am versions of the 917 were unbeatable, especially the 917/30, here in the Sonoco colours as driven by Mark Donohue to the championship in 1973. The classic Can-Am cars, with their 7-litre pushrod motors, were no match for the 5.4 litre flat 12 with the twin turbochargers.

This kit was provided to me by a colleague who had painted it but didn't feel up to the engine and chassis. I've now boxed it up and shipped it back to him.

As always with these Model Factory Hiro kits, a lot of stuff doesn't fit or is excessively flimsy. The fit of the engine cowl and its ridiculously weak hinges are just one of the stories. I did get the doors to open and shut, however.

Sunday, November 2, 2025

Porsche 917/30: Body

The body having been painted by my friend who asked me to finish the kit, I had to get it all to fit before putting on decals. But first I tackled the interior.

This involved some typical MFH fooling around which later required some filing and grinding to get the front clip to fit over it.

Speaking of filing and grinding, the rear cover sits way too high. A lot of grinding inside the cover, plus some filing of various tubes and pipes, improved things but only partially.

In the end I gave up, especially as the hinge is extremely flimsy and is likely to rip out after one or two cycles of opening and closing. So it will get posed next to the car, allowing the engine bay to be seen.

Decals went on OK for old ones and only one or two screwups arose, mainly when I put on the clear a little too heavy at first. The front clip fits OK and the doors open and close, with moderate fit issues when closed. With the hinges set in 5-minute epoxy, I hope they will last.

Upcoming final assembly includes a few details such as mirrors, some rear structure that didn't survive the manhandling and needs to be reinstalled, and the wheels and tires. Sadly this will be one of those "good enough" builds by the time I am done. Stay tuned!

Saturday, May 31, 2025

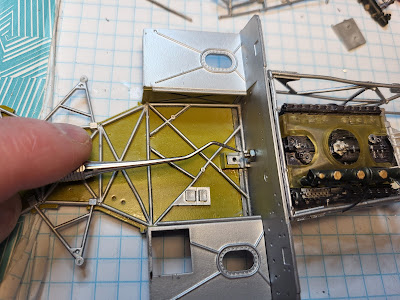

Porsche 917/30: Front chassis

Front tubular chassis bits follow the usual excessively complex MFH approach.

Progress was slow but steady. Making sure every little 0.5 mm socket is drilled out is critical.

The main flaw is the rack, which should have gone in earlier, is bent and the mounting pin i not quite entered into the left side socket.

Front wheels are test-fitted and it all looks nice and square.

Rear suspension and brakes also went on in order to get it sitting on all four as quickly as possible.

The chassis is essentially complete and sits nice and square. The front clip fits nicely but some work will be needed to get the engine lid to sit on it properly. Stay tuned!

Wednesday, May 7, 2025

Porsche 917/30: Rear chassis

The engine is now installed in the chassis and all the chassis tubing bits are done. This includes the turbocharger piping and a few other bits and bobs. This was all surprisingly easy compared to my recollections of the dreaded 908/03; and maybe this reflects the experience I've acquired in building 25 Model Factory Hiro kits since that 908/03, 17 of them at 1/24 scale. Time to dig out the 1971 version of 908/03 kit out of the stash, perhaps?

Next: front tub details, and rear suspension bits. Stay tuned!

Sunday, May 4, 2025

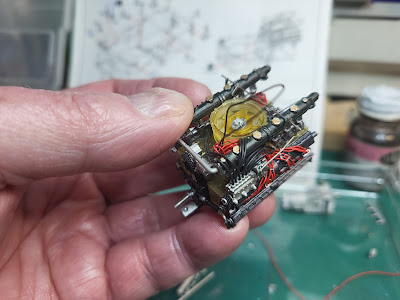

Porsche 917/30: Engine

This is my second MFH 917 motor at 1/24, third overall if you include the 908/03 which is quite similar. So I'm getting better at it knowing what to expect -- photo-etched throttle linkages and two plugs per cylinder among other things. The semi-transparent yellow plastic for the fibreglass bits is lovely. Here is the injector wiring going in, with injectors pointing up into the airstream, a first for me:

The engine is clearly wired up as a pair of 6-cylinder inline motors, where the cross-over exhaust piping in the 908 engine shows it was wired up as a pair of flat fours end to end.

First bank of wiring done. I used Detail Master 0.016" red plug wire for this, because the provided black wire is both too flimsy and too hard to see.

This is the hard side to do, with the injection pump in the way.

The other side (right side of the engine) has less stuff in the way of the plug wiring.

Next: Plunk this all in the chassis where it will never be seen again. Stay tuned!

Wednesday, April 30, 2025

Porsche 917/30: Introduction

A Facebook colleague asked me to help him out with the devilishly complex 1/24 scale Model Factory Hiro kit of the devilishly complex Porsche 917/30 as driven by Mark Donohue. Specifically, the paint has been done, and the engine started; and as paint is my least favourite part of this hobby, I agreed. So the owner of the kit mailed it to me and it turned up about a week ago.

First step was to disassemble the engine as I intend to paint and detail it, even if none of it will be visible once complete. I gently pried off the lovely semi-translucent fan shroud and tossed the rest into the acetone bath to dissolve the CA glue.

Then I got out my lovely new DC drill press and went to work with the 0.016" bit: 12 injectors, 12 injector ports on the injection pump, 24 spark plugs in the cylinder heads, 24 plug wires on the distributors, 4 coil wires on the distributors and 4 coils, all this without once breaking a bit or sliding off the part and driving the bit into my thumb.

Reassembly is progressing. But I know from experience that it is wise to ensure the engine, rear tubular chassis and cockpit tub all line up as early as possible, otherwise you wind up wrestling with a complete but delicate engine, in a complete but delicate chassis, to get it all to line up. So I also got started on these other components.This involved sorting through piles of flexible and poorly formed 1 mm diameter white metal tubing.

Eventually I got to the point of bolting the engine block and rear chassis to the cockpit tub, using a larger M2 stud and nut in place of the provided M1.4 x 3.0 screw. This shows that the rear engine mounts need to be moved forward about 2 mm, a good thing to know at this stage.

Stay tuned, this will only get better.