A number of acquaintances have asked about resin, so perhaps I will use the Audi S1 to illustrate challenges and solutions as I go along.

The Audi is the third Profil 24 resin kit I have tackled, the other two (Aston Martin DBR1, Renault 40 NM) being stalled. There are clearly a range of quality levels when it comes to resin, usually reflected in price.

At the top of the heap is Model Factory Hiro. The resin parts look like styrene and need little or no fiddling to get them to fit. The spun-cast white metal bits need more work, with part lines and dowels needing cleaning up, sockets needing drilling, etc. You pay the price, though, in cash, with prices in the 30,000 to 40,000 yen for the few 1/24 scale kits they still make. (That's $300 to $400 depending on currencies). Add in shipping and you've got yourself one hefty bill. Case in point: the Abarth OT 1300 went together well and is essentially complete; if you look back, you will see that my ongoing challenges with the Porsche 908/03 arise more from the white metal than the resin bits.

|

| The MFH Porsche 908 forward chassis. Excellent resin bits but the spun cast white metal chassis tubes are easily bent. Superb quality at a price. |

At the other end of the spectrum are the large number of transkits provided by Jimmy Flintstone. Poor surfaces, lots of flash and sinkholes, and thick castings that are frequently not straight make any project an exercise in hand-fitting the new body to the donor chassis. The high-quality builds you see in online forums arise as a result of many hours of primer, paint, sand, repeat, followed by (I am guessing) hand fabrication of suitable brackets and mounting braces to get the stance right. Ooof. The low price tag, in the $20 range before shipping, is long forgotten once you make it to that stage.

|

| The styrene hood from the AMT Starliner kit is a poor fit on the Jimmy Flinstone body. Heck, even the Jimmy Flinstone interior is a poor fit on the Jimmy Flintstone body. But, for $20, it's hard to complain. |

Profil 24 is in between these extremes: much cleaner molds and better fit than the Jimmy Flintstone stuff, at a significantly lower cost than the MFH kits which are becoming rare and have always been very expensive. So expect plenty of trimming, sanding and filing, but it all fits.

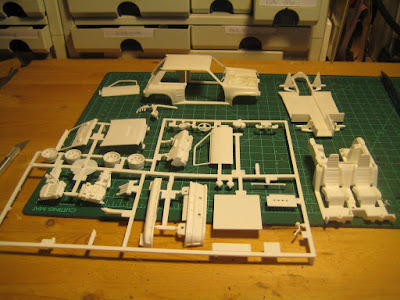

The Audi is probably a good first resin kit to tackle (and is the first Profil 24 kit I bought) because there is very little structural white metal, meaning you can't bend a chassis tube and have it screw up the rest of the build forever; on the other hand it requires a very different mind set than styrene. So here goes.

Washing in alcohol yielded very little in the way of the brown goobers I have seen when cleaning up other resin kits, said boogers being the residual silicone-based mold release agent used in resin. Either I already washed this kit and forgot that I did so, or Profil 24 has done something to make this step unnecessary (using no mold release agent, or one that doesn't stick to the part, or maybe they rinse before packing).

Next was a high level cleanup of flaws in the engine parts and the chassis, then a first coat of Tamiya primer. So far so good; the primer showed up a multitude of little seams and flaws that needed more work. Primer, scrape and shape, primer, repeat. Resin makes more dust than styrene and you should try not to inhale the stuff.

The Tamiya primer went on the chassis well but the Tamiya white, frustratingly, did not. So back into the alcohol bath it all went, and off I went to the auto parts store for some industrial primer. The issue of pale colours in Tamiya paints remains. I have had problems with Tamiya yellow on styrene so I am beginning to think the issue is the paint, not the material; in both cases the standard Tamiya primer went on first. And the Tamiya French blue on the Renault 40 NM worked well. Options are Testors, which is an enamel and requires thinner to remove if it doesn't work; or auto paints that will be pretty permanent.

The chassis includes a number of items that are molded in, such as gearbox, driveshaft and exhaust pipe. This leads to lots of cleanup required to get rid of ugly lumps of resin. While this is admittedly in a location where most people will never look, the door pockets are a problem and will also require lots of grinding.

So two steps forward, three back. Stay tuned...

|

| Molded-in door pockets and roll cage will be difficult to clean up. |