With the 1/43-scale BRM H16 from Model Factory Hiro coming along quite nicely, and with the completion of the Aston Martin DBR1 from Profil 24, I am beginning to think it may be time to get back to the 1/24-scale 908/03, also from MFH. (Updates on the H16 are

posted here)

Regular readers, if any (you are a silent bunch! Is there anyone out there?) will recall this got bogged down over a throttle return spring,

click here. Lurking immediately beyond the spring in terms of complexity were the distributor wiring and injection plumbing. With twin-plug heads and a single distributor, there are 16 plug wires, alternating red and black, leading into the distributor, plus two coil wires. As for the injectors, they are minuscule little spun-cast bits that need to be inserted into the air intakes just right and the clear fuel line then slid over them. At the time, I figured this was a disaster waiting to happen, but since then I have made my own distributors and wired up several engines, so it may be that I am ready to tackle this monster of a kit again.

On the other hand the last couple of efforts have been quite challenging. The H16, at 1/43 scale, has been built entirely while peering through the 4X desk magnifier, and the Aston Martin came with its own challenges. So I decided it is time for a quick break. I dug this kit of the Porsche 907 and 908 out of the stash.

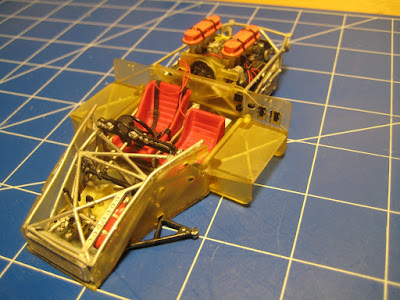

The kit is an odd one which I probably got from eBay. Built by the Japanese company Union Model Company Limited, with an address in Tokyo, the instructions are the usual Japanese with poorly translated English notes. So far so good, but the box art is mainly in French and the floor pan has the name Heller molded into the sill where it is hidden once the chassis is assembled. So I am guessing this is a reissue involving Heller molds being shipped to Japan, and intended for sale in France, although how the instructions, in English and Japanese, were going to play out there is anyone's guess.

The 907 was the successor of the 910 (a rare case of Porsche project numbers not being sequential, at least up to the 996) and was succeeded by the 908/01. Both cars were streamlined coupes with long tails, the differences being mainly in the engine compartment. (The later 908/02 and 908/03 were open bodies with short tails). The streamlining meant high top speeds, even with the 220 to 270 hp available, and while there were some mechanical issues that cost them wins, the cars did reasonably well at Le Mans and elsewhere in 1967 and 1968. (This was smack in the middle of the period when Ford dominated Le Mans with the 7.0 litre push-rod motor out of the Galaxie; it would take the 917 to beat the Fords.)

According to Wikipedia, the 907 was run with both the 2 litre flat 6 as well as the 2.2 flat 8 from the old Formula 1 program; the 908/01 had the flat 8, possibly in 2.2 or 3.0 litre form (the Wikipedia entries for the 907 and 908 are not entirely consistent). Later 908s eventually got a new 3 litre flat 8 making something like 380 hp, which is what is modeled in the MFH kit.

This kit, which can be built up as a 907 or 908/01, has a generic 8 cylinder motor which is clearly a 2.2 in the 907 version: fan mounted on the top of the block, two 4-cyl distributors, and only one plug per cylinder. There isn't enough detail to tell if it is a 3.0 in the 908 version, which (at least in 908/03 form) would have had a fan mounted at the front of the motor, twin plug heads and a single distributor with 16 plug wires.

The kit will be a nice distraction as it is pretty simple (the box says 102 parts) and should go together easily. I'll go for the 907 version since the accuracy of the 3-litre motor is poor. The chassis paint is drying as I write; stay tuned!