The Lotus Eleven was an iconic little racer, and the only kit I have found of it is a resin body, suitable for use as a slot car, made by Profil 24. So I decided to use a spare Tamiya Lotus Seven kit as a base for a what-if Eleven.

The cars had similar wheelbases but there were a range of differences. The biggest, of course, is the engine; the Seven Series 2 modelled by Tamiya had a lightly hot-rodded version of the 1340 cc Cortina engine while the Eleven had the real deal: the lovely Coventry Climax motor in 1098 cc form. Sadly there are no Coventry Climax motors available in 1/24, as far as I know, so the Cortina will have to do. (The Sport version of the Eleven was offered with the 1172 cc flathead out of the Ford Popular, but I would guess that few were made that way, and that any survivors are likely to have had a Climax motor retrofitted).

First step was to cut out the three big lugs molded inside the Eleven body, which were meant to serve as mounts for the slot car chassis. Out came the Dremel with a cutoff wheel; if you do this, beware the dust generated as I gather breathing resin dust is not a good idea. A mask is highly recommended.

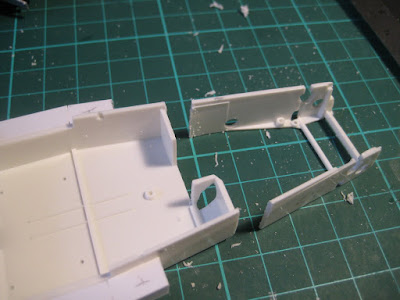

Second step was to start cutting up the Seven chassis so it will fit under the Eleven body. Fenders were the first to go. The Eleven needed some tweaking as well.

Other differences include suspension and brakes. The Sport version (which was the cheapest version) of the Eleven had a solid axle, much like the Seven, and drums; the Le Mans version had a de Dion with discs (inboard at the rear). As well it appears the Eleven still had the swing axle at the front, consisting of a solid axle cut in half, each mounted on a bushing. The Seven will donate its solid axle in back and double A-arms in front, with a disc/drum mix. In the absence of aluminum wobblies, I am waiting for proper wire wheels and tires from Profil 24 as on the first generation cars.

The front fenders came right off, and the rears had to be trimmed substantially. Next door sills were made from 0.250" square tube, and a new dashboard from 0.020" stock.

After cutting off the hood, this is where things stand. The chassis will sit nice and square under the doors, and the main future issue will be to extend the chassis forward to support a hood hinge. The floors will need to be extended to the sills as this was likely one single sheet of aluminum that curves up to meet the doors. The cutout for the exhaust on the left side will also need to be fabricated.

A better firewall will be needed, and the gas filler cap will have to be moved. The Eleven had the battery in back, next to the axle, where the Seven has its gas tank; I will probably leave the battery where it is and assume the gas tank remains mounted above the exhaust pipe inside the cockpit.

Giles seems to find the cockpit a little cramped, which matches my recollection of Loti from my days as a car mechanic: I could get into an Elan, barely, if the top was down; but I couldn't fold my 6'0" frame into the cockpit of a Europa. As well, my size 9 boots were a problem in the footwell. The stories of Colin designing cars that fit him are true. Doris, however, likes it and seems to be impressed with Giles' skills with the non-synchro box.

Stay tuned! For one thing, what will Fred think when he sees Doris's admiring gaze? The plot thickens...