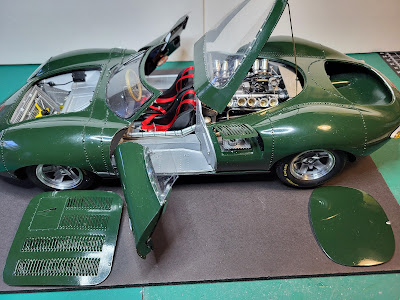

Calling this one done. As MFH kits go, it is relatively easy to assemble, but there were some last minute squeezes. And unfortunately the bodywork doesn't allow for much viewing of the hard work on the chassis and engine compartment.

As always paint is my weak point. More sanding/polishing etc. would have improved things, as well as more care in final assembly where painted panels are attached.

What's next? No idea but there's a 250 LM that is well started. Stay tuned!