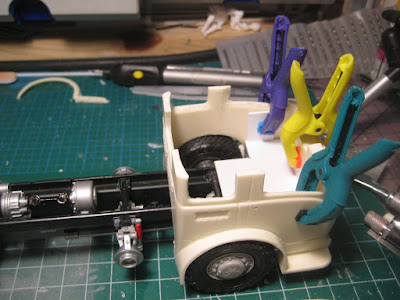

The scratch-built steering linkage (brass rod in the photo above) leads to the White Freightliner steering box attached to the MAZ chassis under the floorboard. The linkage is correct, except that it might foul the wheels as they steer. The mechanism as provided in the kit disappears into the engine compartment, where it is out of the way of rocks or land mines, but where it interferes with the Cummins. As this is meant to be a civilian vehicle, there is no need to beware of land mines.

On the other side of the chassis, a range of brass pipes replace styrene oil pipes that proved to be a little too flexible when faced with my clumsy big mitts. One appears to be feeding oil to the Cummins motor mount but we'll let that go; the MAZ kit had no engine and these parts just sort of disappeared into the engine compartment.

The interior will be a squeeze for my buddy Fred. Fred and his lady friend Doris came into the house with the Lincoln Futura kit and will be part of the road testing and cockpit evaluation team going forward, once I do something about their pasty-white complexions.

Colours mimic the proposed body paint. The dashboard will go into the body once it is painted, then the floorboards, and finally the steering wheel will need to be inserted through the windshield and dropped on to the column.

Moving on to the body: Cutting is complete, and there is enough left over to build mudguards over the second axle.

Initial putty application is shown here. Several rounds of putty, primer, sand, repeat were required.

Dupli-Color primer-sealer remains my favourite to seal resin and identify high and low spots. This primer does a great job of filling small holes and scratches. I find it to be better than the darker sandable primer which includes a polymer of some kind, and which isn't well suited to Tamiya paints or primer. (I know there are dissenting opinions out there and I'd be glad to hear them.)

Final application of Tamiya primer over the Dupli-Color is shown here. I feel that the Tamiya primer, which works very well on styrene, doesn't do at all well on resin, no matter how clean it is, because the Tamiya gets sucked into pits and pores and doesn't ever stick to the surface. The primer-sealer provides a surface the Tamiya primer can stick to.

Next will be the final paint, probably a 3-tone arrangement. Stay tuned!