It's just over 5 weeks between opening the box and completing it; this included Christmas but there were no other competing builds. I worked on it most days, though, at least an hour or more, a total of 60 to 75 hours or more. Overall I am quite pleased with the outcome.

I love the little tie-downs for the engine lid and front cover, made from 5 pieces of photoetch and a little rubber band. I also like the detail of the grille.

The Model Factory Hiro kits keep getting better; this one went together with minimal fuss or major screwups. Or maybe I'm getting more experience... this is the third one at 1/12 scale.

And maybe you've noticed the three all have wire wheels... as does the 1/12 scale Honda RC 166 motorcycle. That's a lot of spokes...

Alfa P2: 4 rows of 12 spokes = 48 per wheel, 192 total

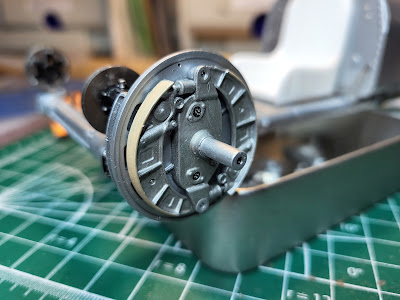

Type C: 4 rows of 14 spokes = 56 per wheel, 224 spokes

Sharknose: 6 rows of 12 spokes = 72 per wheel, 288 spokes

RC 166: 2 rows of 18 spokes = 36 per wheel, 72 spokes

Total: 776 spokes. Gack.

So what's next? Styrene most likely! And no spokes.