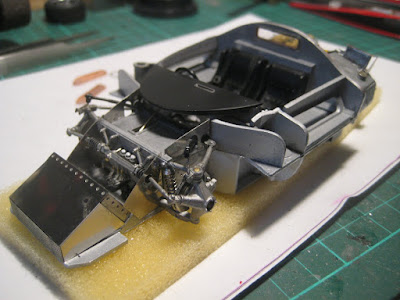

The Model Factory Hiro kit is on a par with the Ford P68 just completed, but it is such a beautiful car, and the kit is so rare, that I feel intense pressure to get it right.

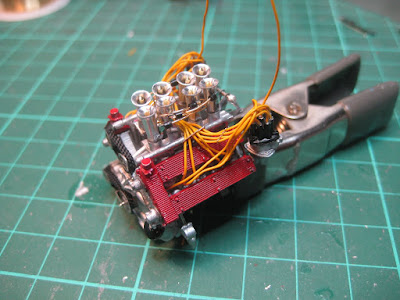

So starting with the 'easy' bits: The engine is now complete. The 2-litre V8 had four cams, 16 spark plugs and two distributors, each supplying one plug per cylinder; with SPICA fuel injection, the Interweb states 230 hp at 8,800 RPM for the road version, and up to 250 for the race version. Not a barnburner by today's standards, but enough for a large number of period class wins as well as an outright win at the Targa Florio where small and nimble is a big advantage.

Plug wires are Detail Master 0.016", or just over 3/8" at scale, so a bit large but easier to handle than the 0.013" supplied with the kit. They also stand out more.

Fuel injection pipes are 0.013", 28 GA craft wire, with short bits of black tube to join them to the photo-etched injectors. This is better than the clear, relatively inflexible tube supplied, because it is easier to handle, but not as realistic as a clear pipe.

Belts are made from microtape supplied in the kit. The throttle slides have bellcranks and a photoetched crank to pull on the fuel feed in the pump located between the banks of the V.

Overall I am quite happy so far. But I've usually found engines to be usually pretty easy; the challenge as always with these kits will be getting the chassis straight and snug enough to fit under the resin body. But I am deploying my new secret weapon, a new LED desk lamp with large 3X magnifier built in. So stay tuned!